Carbon Steel ASTM A105 Flanges are high-strength, forged carbon steel piping components designed to connect sections of pipe, valves, pumps, and other equipment in piping systems. These flanges are produced following the ASTM A105 specification, which defines the requirements for forged carbon steel materials suitable for ambient and high-temperature service in pressure systems. Known for their robustness and durability, ASTM A105 flanges are widely used across industries, particularly in oil and gas, petrochemicals, power generation, chemical processing, and water treatment.

ASTM A105 flanges are manufactured through forging processes, which enhance the material's strength and durability. They are made following international standards such as ASME B16.5 (pipe flanges and flanged fittings), ASME B16.47 (large-diameter flanges), and MSS-SP-44. These standards ensure the flanges' compatibility and quality for high-stress, high-pressure applications.

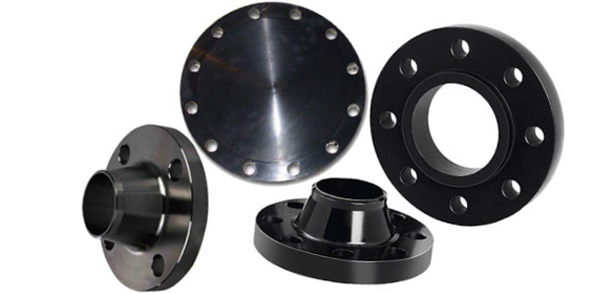

Product Overview:-

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

This material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187.

Specifications:-

| Specifications | ASTM A182, ASME SA182 |

| Size | 1/2″ to 48″ |

| Standards | ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605. |

| Pressure Ratings | Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600 |

| Flange Face Type | Flate Face, Raised Face, Ring Type Joint |

| Coating/Surface Treatment | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated. |

Benefits:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Conclusions:-

Carbon Steel ASTM A105 Flanges play a vital role in ensuring the safe and efficient transport of fluids and gases in piping systems. With their high strength, thermal resistance, and cost-effectiveness, they remain a popular choice across various industries requiring robust and reliable piping solutions.

Carbon Steel ASTM A105 Flanges are an essential component in industrial piping systems, providing reliable and durable connections for high-pressure and high-temperature applications. The ASTM A105 specification ensures that these flanges deliver exceptional strength, thermal stability, and weldability, making them suitable for demanding environments such as oil and gas, petrochemicals, power generation, chemical processing, and water treatment.

Email id:- [email protected]

Contact Number:- 8879709191